United Mert Makina is a combination of two leading manufacturers of machinery for the production of mattresses, United Mattress Machinery from USA and Mert Makina from Turkey. With over 75 years of experience in the industry between Michael Porter and Mert Makina, United Mert Makina has established itself as a trusted supplier of advanced machinery and equipment for mattress production.

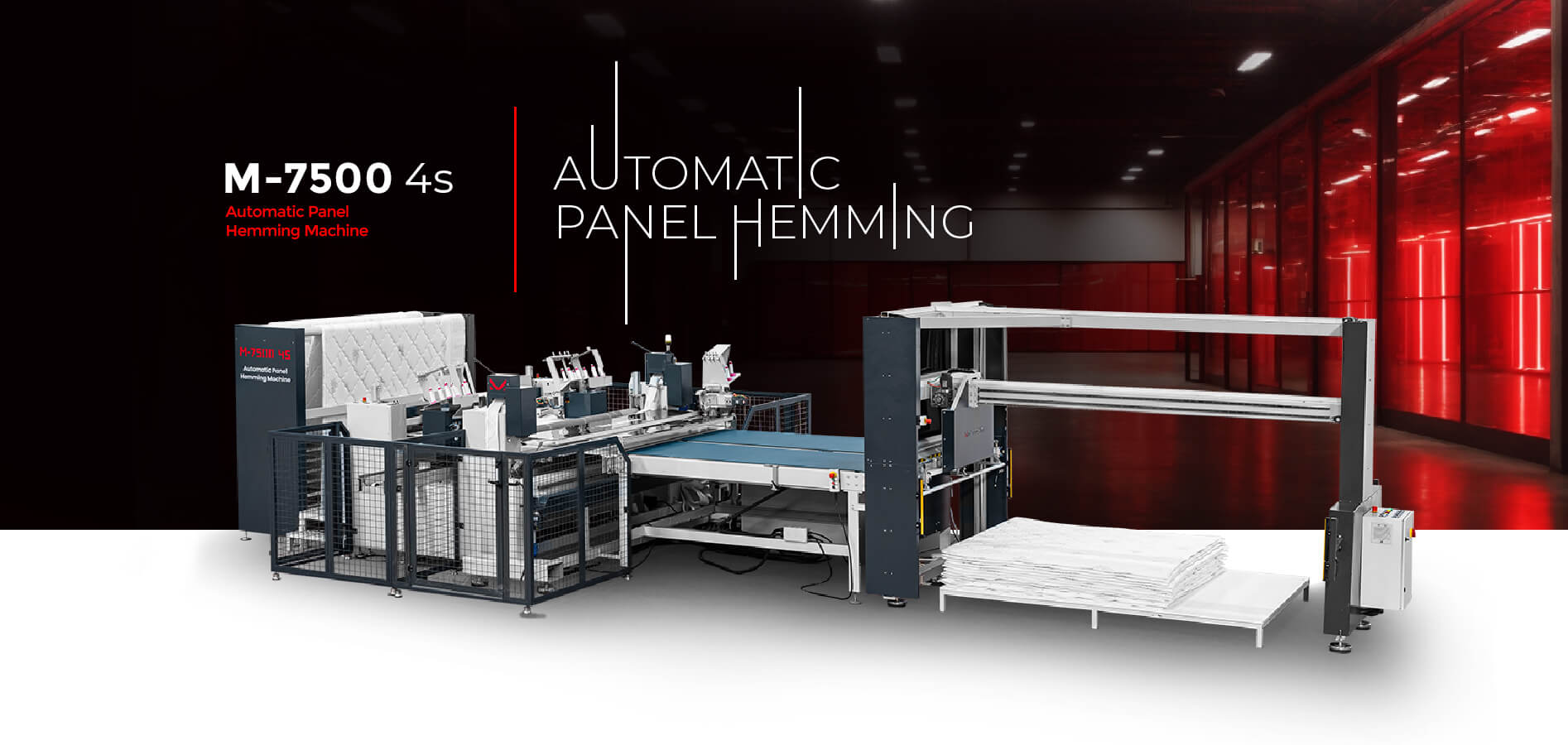

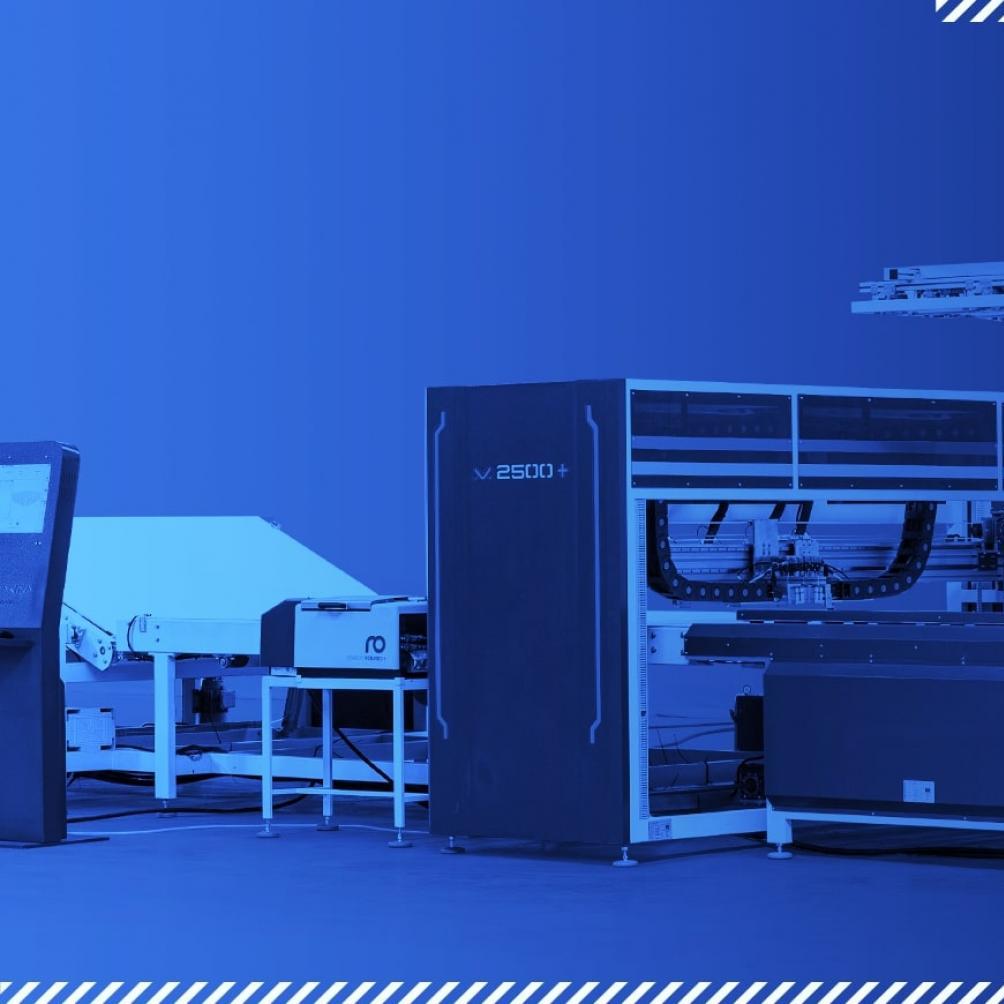

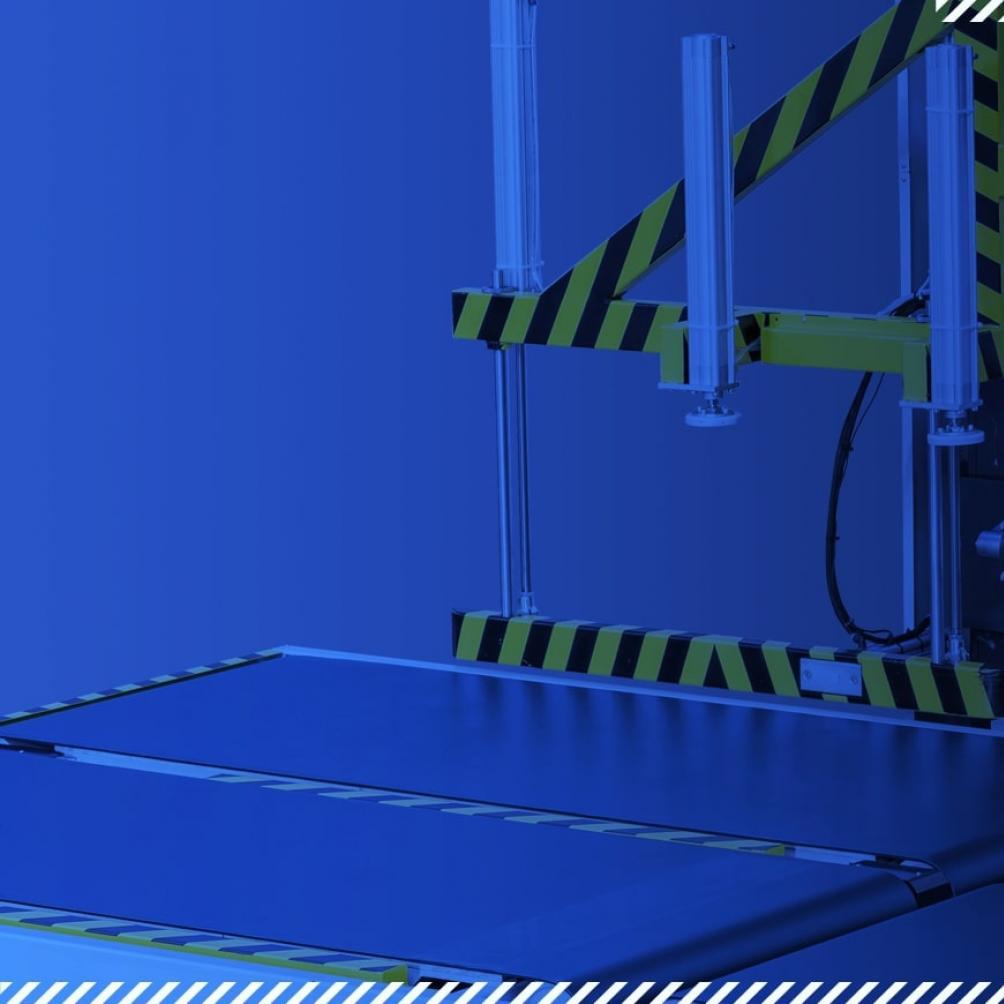

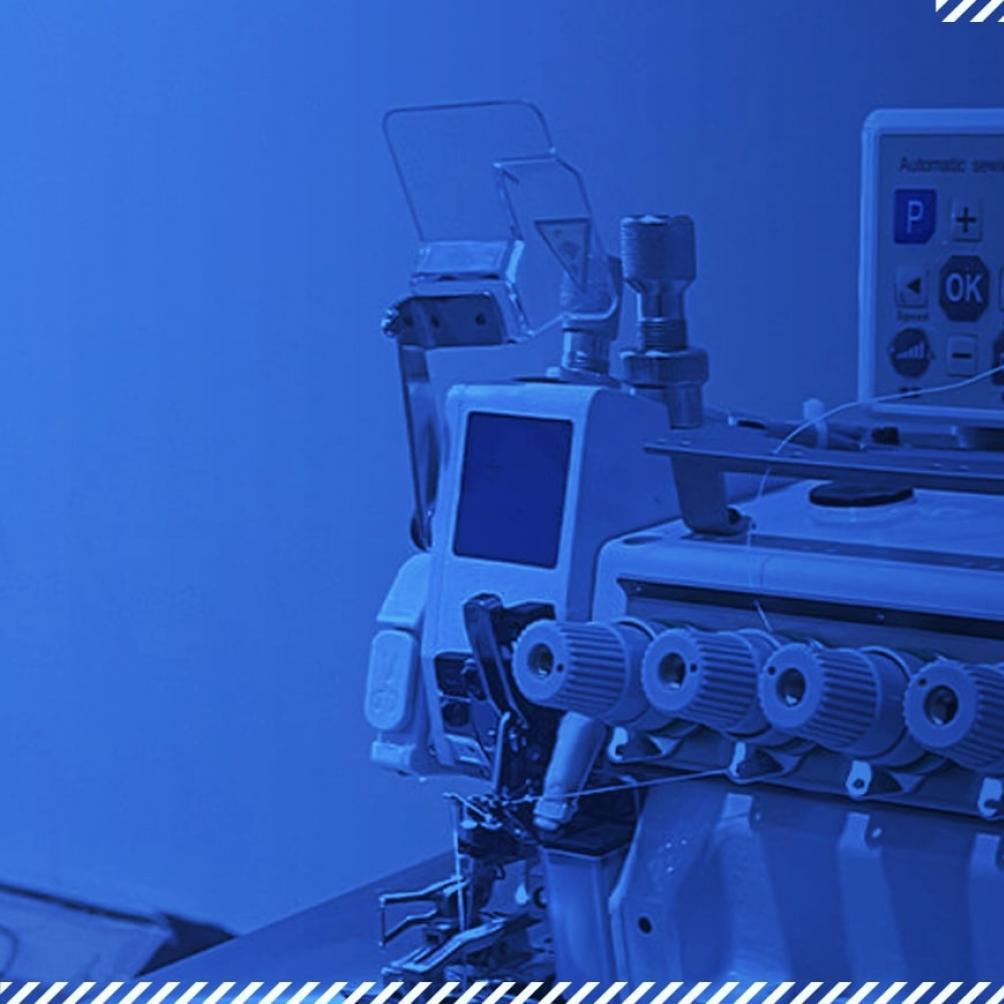

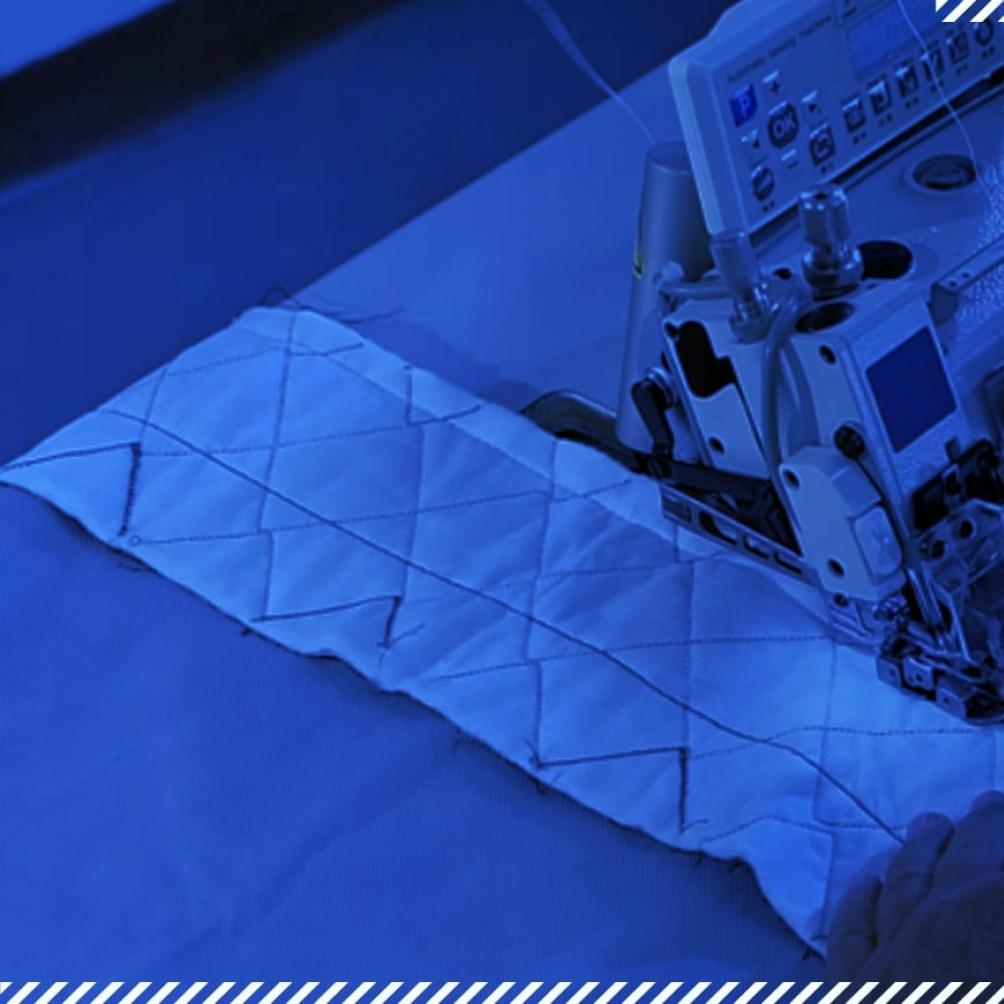

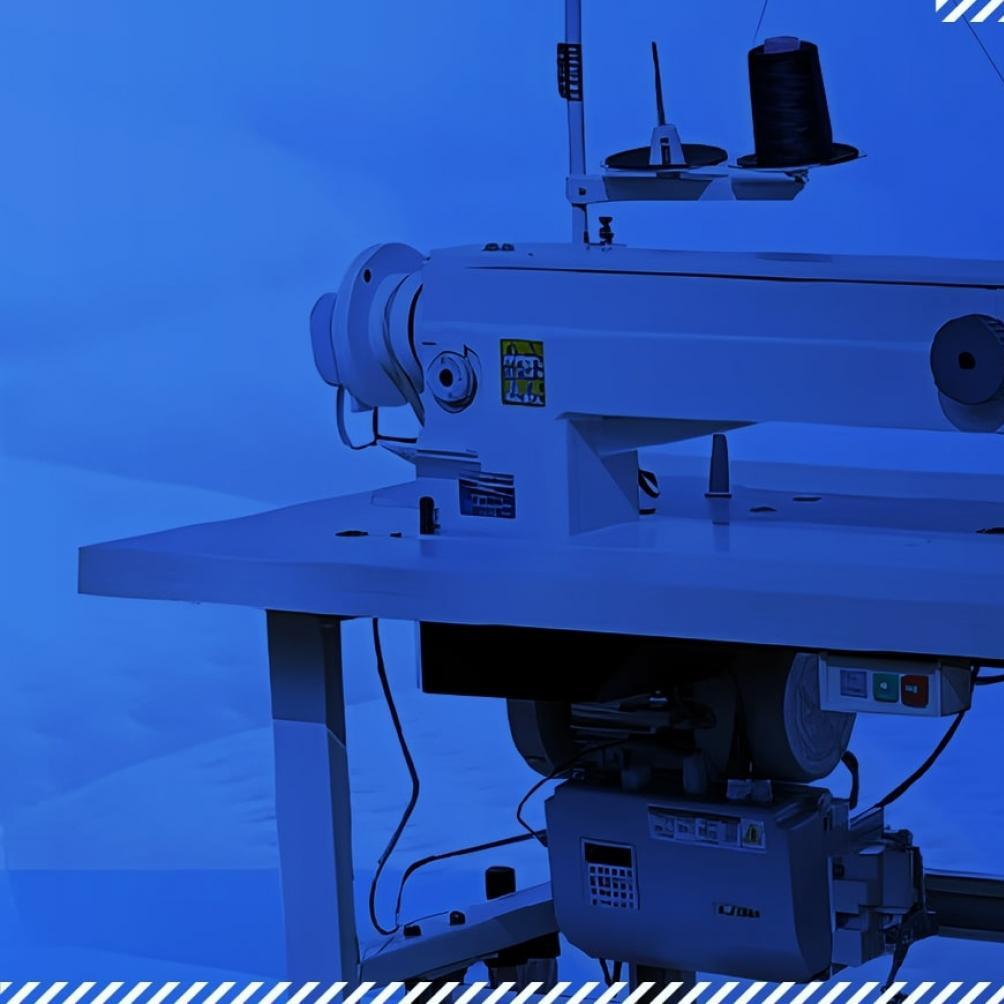

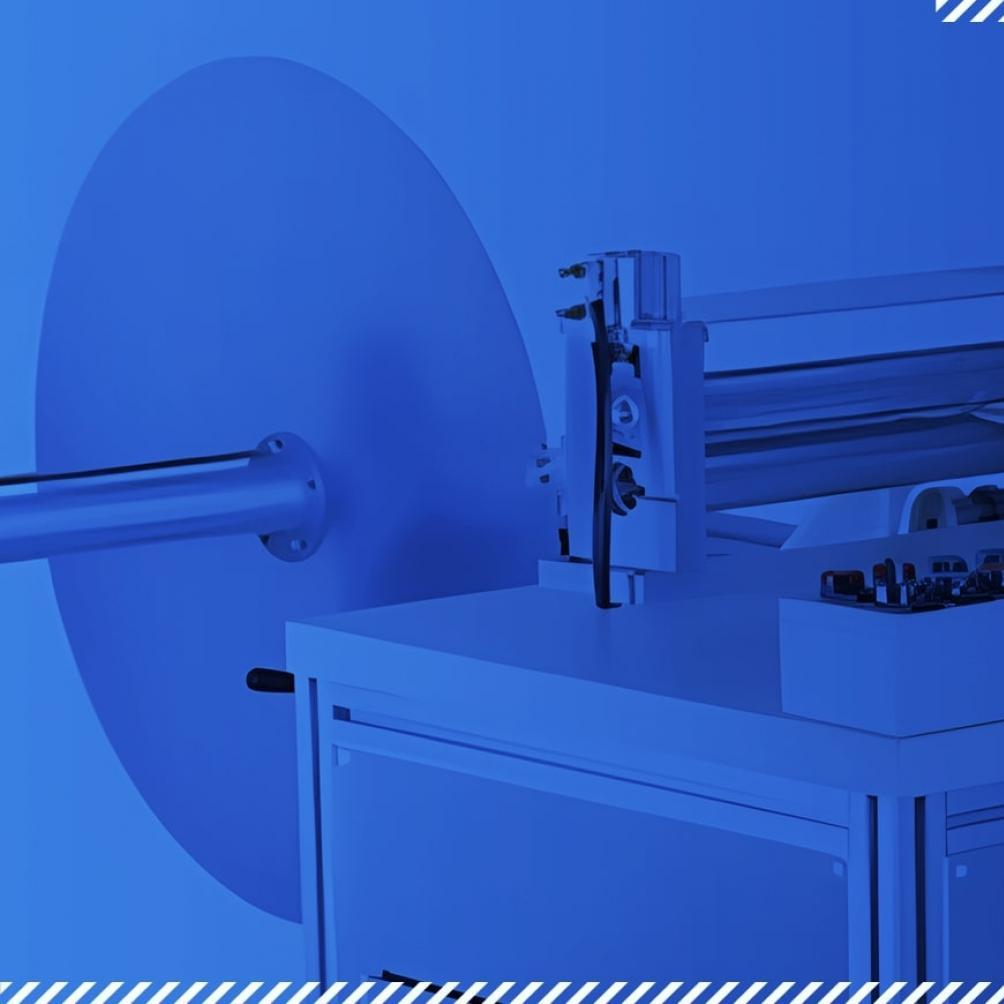

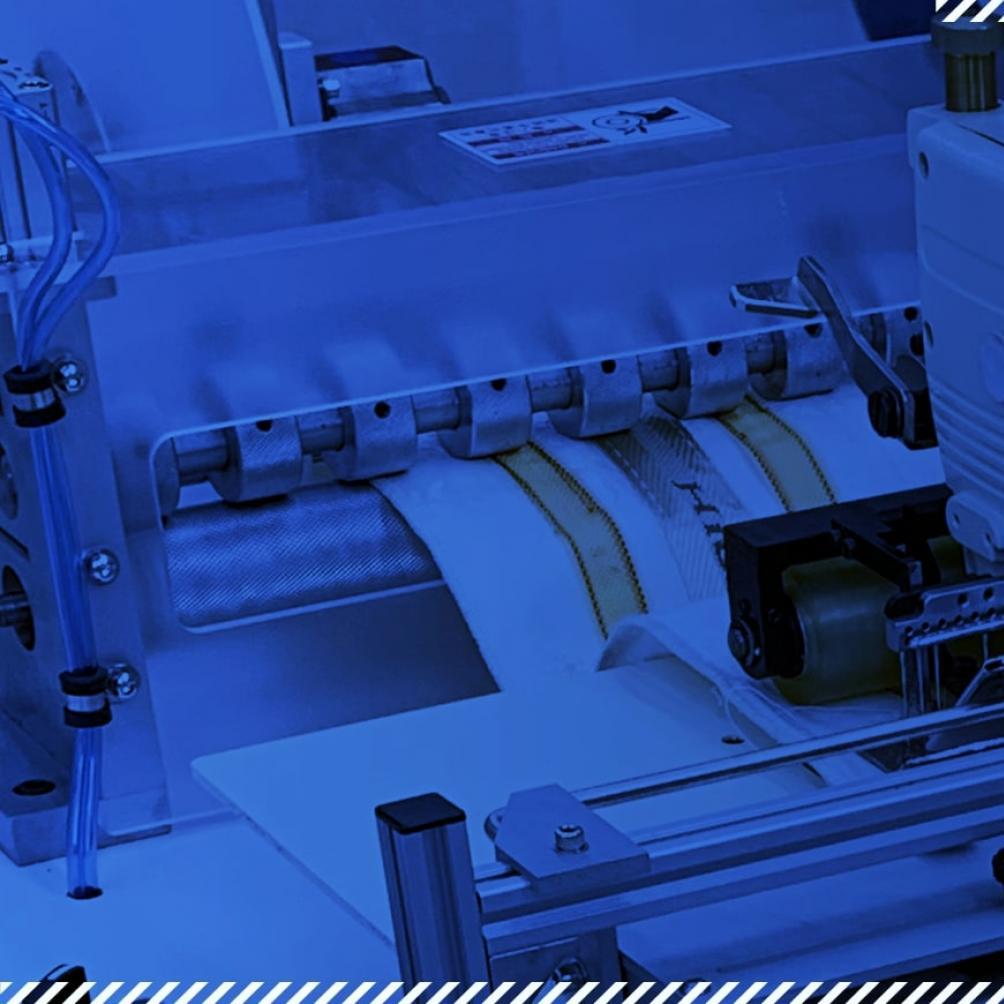

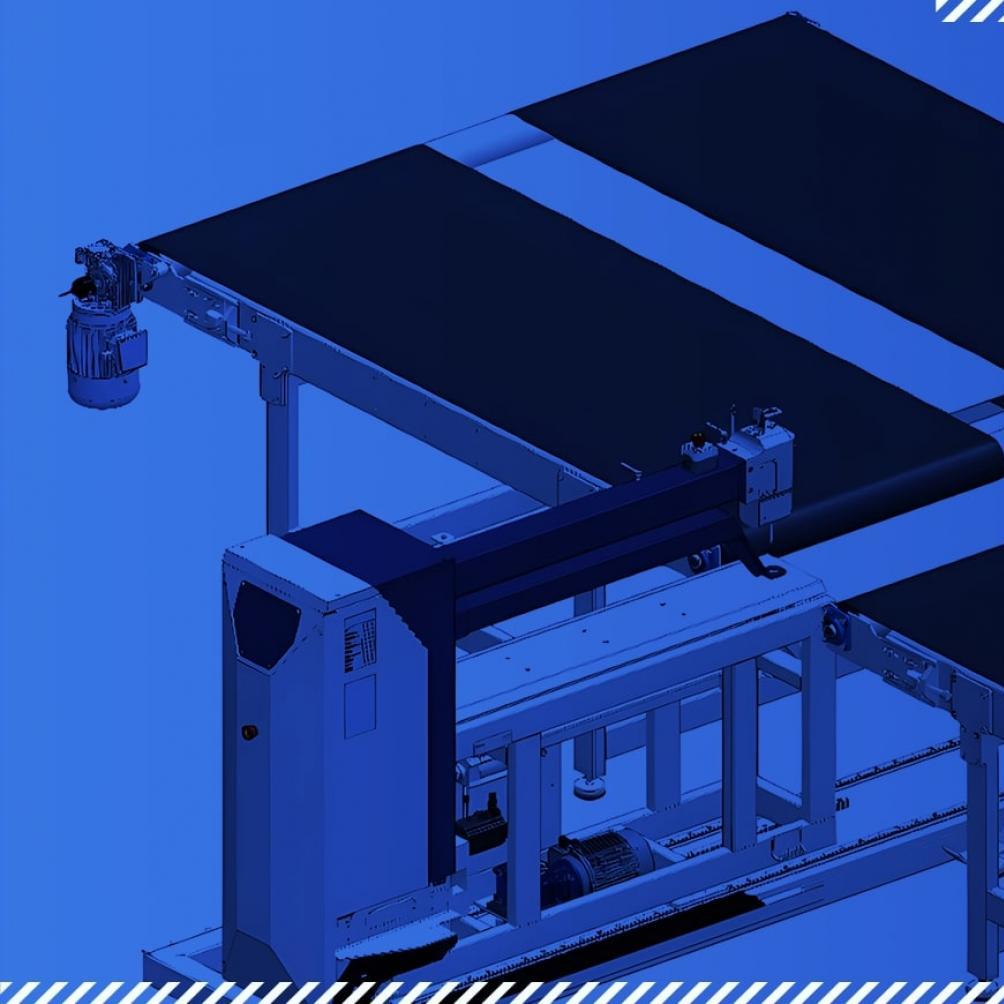

UMM is offering the widest range of machines for different stages of mattress production, including quilting machines, tape edge machines, flange machines and half cappers, roll packing machines and automatic production lines for glue and packaging. All of our machines are designed and manufactured with the latest technology and are known for their efficiency, precision, and durability. The customer list for United Mert Makina speaks for itself.